VOC and a reduced number of plants

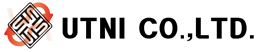

VAPOR RECOVERY UNIT(VRU)

VRU is the VOC Treatment System that can satisfy environment and economic at the same time.

In the raw materials and products from the refinery and petrochemicalfactory process recovery process

Is the vapor generated during storage in facility to prevent air pollution as well as the recovery of the

vapor is recovered by recycling.

Vapor generated in the respective facilities as the adsorption tower in the adsorption process is mainly

Composed the hydrocarbon and to regenerate in accordance each cycle the adsorbent by pressure And the desorbed Vapor is recovered by liquefaction(absorption, condensation).

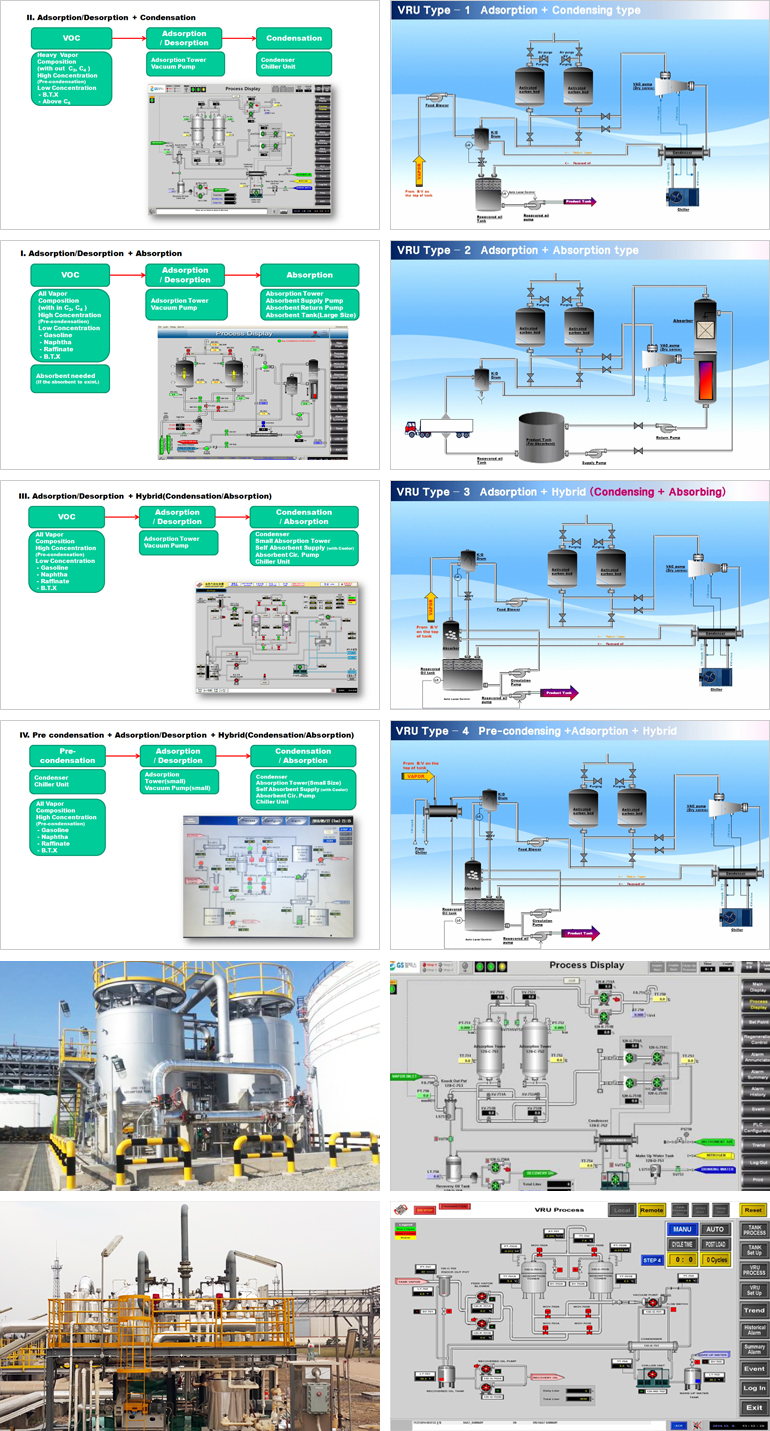

Stage-III VRS(Vapor Recovery System, VRS)

VRS recover gasoline vapors through normal underground storage tank(UST) evaporation during gasoline deliveries to UST in the GS(Stage-I) or during gasoline injection into the car(Stage-II)

Occurring gasoline vapors which consist of HC vapor mixed air flow into the VRS and are then recovered as resalable gasoline by using chiller unit (immediately liquefied) and adsorption unit filled with activated carbon(A/C) as an adsorbent ,vacuum pump for desorbing HC vapor, absorber for absorbing HC vapor. Also VRS can recover at least 98% or more of the emitted vapors.

VRS Type : Hybrid (Skid mounted)

Components : chiller, A/C bed, VAC pump, LCP, Instruments

Adsorbent : Activated carbon 100%

Design capacity : 20/30/60 kL/hr

Kind of Vapor : Saturated gasoline vapor in the UST

Vapor Inlet Temperature : Max 50℃

Inlet vapor pressure : 100mmWC or below

HC concentration : 35 vol%

Utility : Electric power - 3ph 400V 50Hz

Installation area : Hazardous area

Electric parts : consist of explosion proof (ExdIIBT4)

Footprint : 2.4m x 3m

Highly efficiency of gasoline recovery ( 98% or more)

Recovery ratio : Max 0.18% at 35vol% (1.77L/KL)

Vent to clean gas (Low emission , <10g/m3) for 24hrs

Possible to eliminate the non-condensed light VOCs

No need vapor return cycle at the unloading by Truck

No need to modify exist piping line

Small footprint (2.4m x 3m)

Easy to Install (Skid mount type)

Long life time : over 10 years (based on the activated carbon)

No change to GS operations, 24hrs continuous operating

Safety system : available in hazardous area (ExdIIBT4)

Easy to operation and safety shut-down(by PLC)

- Prevent hot spot in A/C bed

Low energy consumption

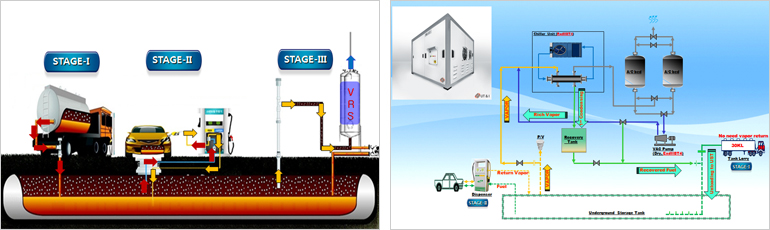

SOLVENT RECOVERY SYSTEM(SRS)

SRS is to recover the VOC components (Solvent) of an exhaust Gas generated in the production process As a technique for recycling, the VOC Treatment System that can satisfy environmental and economic at the same time.

Solvent components of an exhaust Gas is treated by adsorption and when activated carbon is

Saturated to reproduced with Steam, and to recover back to absorption, And VOC components

discharged during reproduction is recovered by condensation to the Condenser.

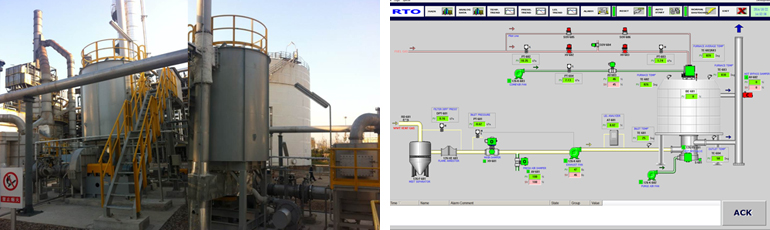

REGENERATIVE THERMAL OXIDIZER(RTO)

RTO plant is removed to reacts with oxygen facility to harmless substances(CO2, H2O) in low concentration VOC(Hydro Carbon) and the odor component at a high temperature(800℃)

RTO is composed structure of a Chember and in the interior is divided into several Zone Separated and is circulated by the Rotary Valve of lower role for the inlet and outlet through a number of Zone.

Processing efficiency is good as the efficiency of more than 98% The heat storage efficiency of 95% less fuel consumption by more than structure.